27 Products

filterL(+)-lactic acid (dextrorotatory) 21% food grade 100 ml HDPE dropper bottle

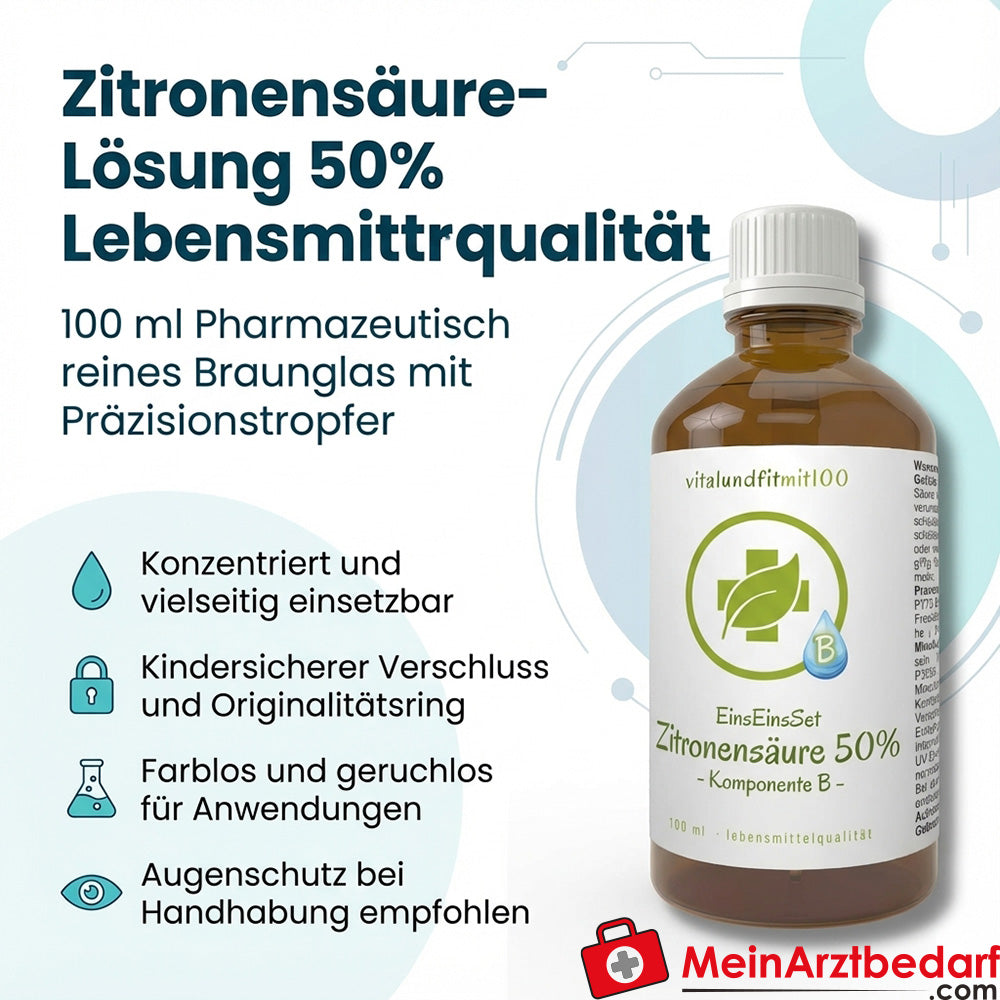

Citric acid solution 50% food grade 100 ml amber glass with precision dropper childproof

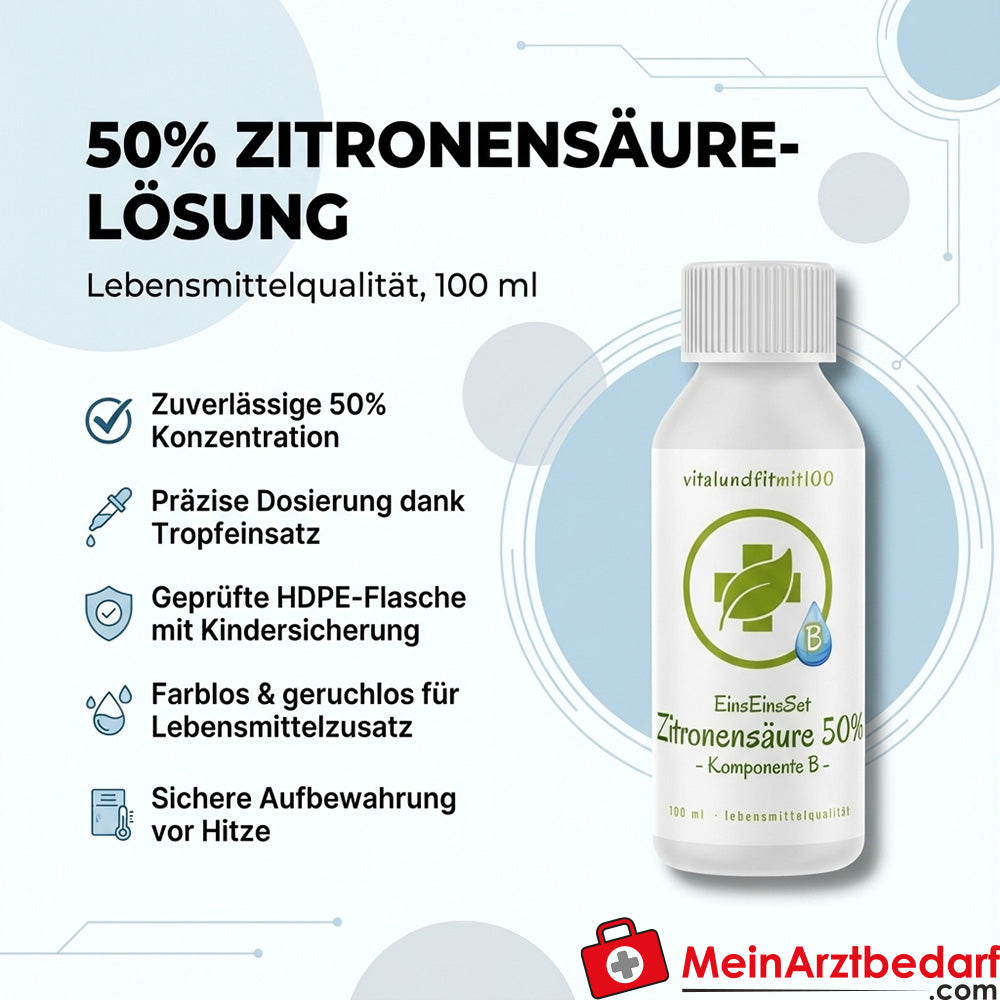

Citric acid 50% solution (food grade) 100 ml HDPE dropper bottle

Everything loaded

Water Treatment & Reagents

Areas of use and application areas

Products from the category Water Treatment & Reagents serve to provide quality-controlled water, chemical analysis and sample preparation and preservation. Typical application situations include the preparation of laboratory solutions, the cleaning and disinfection of devices, the checking of water quality as well as the preparation and dilution of buffer and reagent solutions for further use in diagnostic and analytical processes.

Product types and typical solutions

The selection includes systems and consumables for different purity requirements as well as chemical reagents for testing and preparation:

- Water treatment systems (softening systems, reverse osmosis modules, conductivity and flow measurement)

- Filter cartridges, membrane filters and spare parts

- Distillation and ultrapure water products

- Reagents, buffer sets and standards for calibration

- Test kits for pH, chlorine, conductivity and ion analysis

- Preservatives and disinfectants for water supply systems

Advantages in everyday practice and laboratory life

High-quality components and suitable reagents ensure reproducible results, reduce sources of errors and simplify routine processes. Appropriate water treatment minimizes contamination, protects measuring instruments and extends the life of analytical devices. Calibratable reagents and standards allow valid quality controls and make it easier to document test results.

Quality, safety and selection criteria

Purity class, flow rate, compatibility with existing equipment and documented specifications for storage and shelf life are crucial when making your selection. Products from manufacturers such as Merck, Sartorius and Hach often offer tested standards, certificates and technical support information that support integration into existing work processes.

Recommended application instructions

Regular monitoring of conductivity, pH and microbacterial load as well as scheduled changes of filter media and reagents ensure consistent results. Documentation of calibrations and batch information helps with traceability and quality assurance.